Oil plays a part in just about every industrial process on

earth. While oil can play crucial and beneficial role in industrial operations, it can also cause

many challenges once it has served its purpose and ends up in the wastewater stream.

Oil plays a part in just about every industrial process on

earth. While oil can play crucial and beneficial role in industrial operations, it can also cause

many challenges once it has served its purpose and ends up in the wastewater stream.

To increase the efficiency of wastewater treatment processes and maintain environmental compliance, organizations must first remove the oil before repurposing it or the water, before discharging water to the municipality, and before chemical treatment or filtration of the water.

If not removed continuously and effectively, oil in wastewater can cause equipment malfunction, process inefficiencies, undesirable working environments, fines from the municipality and/or the EPA, and increase downtime and maintenance.

Related read: 5 Red Flags That Your Oil Skimming Solution Isn’t Reliable

There are many skimming solutions and oil removal systems available for different oil-on-water situations. Each scenario may require a different solution, but in many cases, the solutions our experts recommend include a Brill® oil skimmer with a Free-Floating Collector Tube®.

Floating Tube-Type Skimmers: A Practical Solution

Tube skimmers run on a simple concept: continuously remove oil from the surface of the water using a closed-loop collector tube that floats on the surface of the water, attracting the floating oil or grease.

They are flexible, easy to install, and low maintenance.

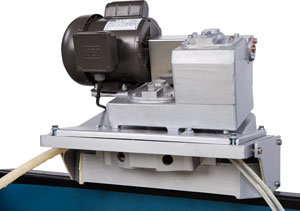

In this video, see one of our tube-type oil skimmers in action: the Model 5H. This unit is used for above ground tanks, parts washers, and other applications where the skimmer can remain within three feet of skimming area. In the demonstration, the team pours five gallons of oil into the water. See how the collector tube floats and oil adheres to the outside of the tube— collecting only oil, leaving the water behind—and the oil is removed from the tube as it passes through the skimmer.