Summary

The oil water problem was critical, and something needed to change. Fast.

After years of relying on the wrong type of oil skimmer for the plant’s oil separation needs, the maintenance and engineering department turned to a vacuum truck service. Unfortunately, the company soon realized that the cost of frequent visits to the site was much too expensive, and as soon as the vacuum truck would leave, oil would immediately accumulate in the pit once again. It was a costly and inefficient process that would not be sustainable.

After conducting further research on oil-water separation and oil skimming solutions, the facilities management team found Oil Skimmers, Inc., and learned about our extensive experience in separating and removing oil from water.

After assessing the plant’s application and thoroughly understanding the complex challenges it faced, Oil Skimmers provided a multi-stage oil removal system consisting of a Model 6V Brill® floating tube oil skimmer with an insulated Hi-Flow Sludge Funnel Spout, both mounted to a customized Guard Rail Mounting System attached to the customer’s safety guard rail surrounding the wastewater pit.

The comprehensive oil removal system designed by Oil Skimmers addressed EVERY issue the plant faced, and the plant reports that they are satisfied with their new oil removal solution.

“This system really checks all the boxes. We are saving lots of money because we don’t need the vacuum trucks anymore. We are saving lots of time and labor because our maintenance team can trust the new system to just plain work. We’re confident now that we have the right oil removal solution in place. It’s effective, efficient, rugged, and reliable—all year round.”

— Plant Facility Manager

The Full Story

After several years of relying on an oil removal method that was inefficient and ineffective, a soybean processing operation turned to a vacuum truck service for help. Although this service was able to remove oily water from the company's below-ground pit, it had to be done several times each month, which was far too costly to sustain in the long run. Consequently, the plant's maintenance and engineering department sought an oil removal process that was efficient, cost-effective, and sustainable.

Operational Considerations

The plant, located in the Midwest, operates a high-volume facility that produces soybean oil. The production of soybean oil is a complicated process that involves cracking soy kernels with hydraulic pressure using a hexane solvent. By-products of the process include soybean meal, which is used for animal feed, and industrial biodiesel fuel.

The plant’s wash water contains waste soybean oil with trace amounts of hydraulic oil that drain into a below-ground collection pit in an outdoor wastewater management area. Due to the presence of flammable hexane solvent used in the extraction process, the pit is surrounded by safety guard rails and is rated as an explosion-proof zone.

The Source and Cause of the Problem

When the wastewater management area was originally constructed, drum-type oil skimmers were installed in the pit to continuously recover oil floating on the surface of the wastewater. Unfortunately, the type of drum-type oil skimmer used presented several critical problems in this application:

1. The drum oil skimmer was designed to float, causing oil to build up both around and within the unit, interrupting the flow of oil and preventing it from being pumped away to a collection vessel.

2. The rotating oleophilic element floating in the oils follows a fixed path, leading to the accumulation of floating debris in front of the device, which blocked the oil from reaching the skimmer.

3. Even when there was no floating debris blocking the oil skimmer, if the oil didn't find its way toward the skimmer, it couldn't be collected because the drum oil skimmer being used lacked a reaching mechanism to collect oil, unlike floating tube oil skimmers.

The constant monitoring and manual intervention required to keep the drum-type oil skimmer operational became a burden for the maintenance staff at the processing plant. During the cold winter months, low temperatures would cause the oil to solidify, exacerbating the plant’s issues and inefficiencies. Consequently, the plant stopped using the drum oil skimmers and retained a vacuum truck service to address its oil removal needs.

However, when the plant started using the vacuum truck service, old oil removal issues were replaced with new ones. The facility’s oil removal needs were ongoing, meaning that as soon as the vacuum truck left, oil began to immediately re-accumulate in the pit. Increasing the frequency of visits to mitigate the issue became quite costly.

Making matters worse, whenever the vacuum truck sucked oil from the pit, it also removed high volumes of water. Since vacuum truck services charge by total volume removed, the facility incurred additional and unnecessary expenses, making the vacuum truck an unsustainable oil-water removal solution.

“The vacuum trucks were effective, but certainly not efficient, and very expensive. We ended up paying for them to remove not just the oil, but also a lot of water that got taken away with it.” — Facility Manager

The facility's management team recognized the need for a more efficient, cost-effective, and sustainable approach to their oil removal challenges. Online searches led them to the Oil Skimmers, Inc. website, where they reviewed Oil Skimmers’ complete line of oil skimmers, skimming systems, and oil-water separators. They learned about the company's considerable experience and application knowledge gleaned from over 50 years in the oil removal solutions business.

After submitting an initial inquiry, Oil Skimmers promptly contacted the plant’s team to schedule an on-site wastewater assessment.

Oil Skimmers’ Systematic Approach

Oil Skimmers thoroughly assessed the plant’s wastewater pits and the entire wastewater management area.

“The customer had a good understanding of the problem, and we reviewed all of the plant’s requirements,” said David Cehlar, Regional Manager at Oil Skimmers, Inc. “We put a team together, listened carefully, and got to work. Based on Oil Skimmers’ 50+ years of experience in oil skimming and oil removal solutions, we were able to confidently map out an ideal solution for the plant’s needs.”

Ideal Solution #1: Effective and Efficient Oil Collection

Oil Skimmers, Inc. prepared engineering renderings of the site, designed several possible solution sets, and reviewed them with the soybean plant's management team.

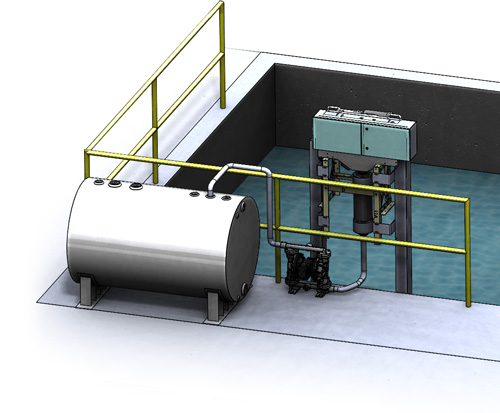

Oil Skimmers, Inc. provided a multi-stage oil removal system consisting of a Model 6V Brill® floating tube oil skimmer with an insulated Oil Skimmers, Inc. Hi-Flow Sludge Funnel Spout, both mounted to a customized Oil Skimmers, Inc. Guard Rail Mounting System attached to the customer’s safety guard rail surrounding the wastewater pit. The “guard rail mount” was customized so that the oil skimmer could reach beyond the wall of the pit to avoid interference and extend high over the pit to leverage gravity in moving the oil once picked up. The collected oil was kept in a custom-designed heated reservoir before being pumped into a nearby collection tank.

Unlike drum-type oil skimmers, the Brill floating tube oil skimmers are suited to the plant’s unique application. They are designed for consistent operation with minimal maintenance required. The Brill floating tube oil skimmers utilize a closed-loop Free-Floating Collector Tube™ to pick up the oil. In the Brill system, only the collector tube touches the thick, oily water. The tube floats freely on the water’s surface, allowing the oil to adhere to the outside of the tube, which is continuously driven across the surface of the water and pulled into the system. There, it passes through a set of scrapers that remove the oil before feeding the tube back into the pit to collect more oil.

The tube is designed to attract only floating oil, allowing the water to remain in the pit. The collector tube is unaffected by floating debris and automatically adjusts to fluctuating water levels. Because the tube doesn’t follow a fixed path in the oily water, it is highly effective at continuously picking up oil.

Ideal Solution #2: Moving the Oil to a Collection Tank

Once the oil is picked up by the Model 6V oil skimmer, the next challenge that Oil Skimmers addressed was designing a system for moving the oil to a designated collection tank. The waste oil from soybean processing requires operating temperatures of 170 degrees to keep flowing and prevent solidification.

To maintain the viscous oil flow once it is recovered by the skimmer, Oil Skimmers employed its Hi-Flow Oil Discharge System. The Hi-Flow was designed to accommodate the thickest and most difficult fats, oils, and greases that would choke other collection systems. Thick oil recovered by the Model 6V drops directly into the Hi-Flow’s collection spout, which promotes oil flow and prevents buildup. The spout can be heated and insulated to maintain the 170°F temperature required to keep the oil flowing.

The Hi-Flow spout directs soybean waste oils into a custom-designed oil collection reservoir sitting directly below the Hi-Flow’s spout, allowing enough oil to accumulate before a 2” air-operated double diaphragm pump transfers it to a nearby 300-gallon tank. The pump is controlled by an adjustable pneumatic timer in the system’s explosion-proof control panel, which regulates the transfer of oil from the collection reservoir to a larger tank. When the pump activates, the oil is transferred from the reservoir to an Oil Skimmers’ 300-gallon collection tank that is heated, insulated, and explosion-proof.

The entire system was wired to an explosion-proof control panel, which included controls for the oil skimmer, thermostat, heat, and transfer pump.

Performance and Cost-Saving Results

The soybean processing plant reports satisfaction with their new oil removal solution, and all components of the system are performing as designed.

“The waste oil is being skimmed and is flowing easily to our collection tank – even when the temperature drops below freezing. No more oil build-up like our old skimmers.”

— Facility Manager

The comprehensive oil removal system designed by Oil Skimmers, Inc. addressed each and every one of the issues the plant experienced with their previous solutions:

1. The Brill floating tube oil skimmer doesn't clog, doesn't get blocked by debris, doesn't require frequent maintenance or adjustment, and doesn't pick up a lot of water.

2. The Hi-Flow funnel spout keeps the thick oil flowing.

3. The Guard Rail Mounting System places the system in an ideal position for operation, access, and maintenance.

4. The collection reservoir and transfer pump regulate the flow of recovered oil to the 300-gallon tank.

The Facility Manager added, “This system really checks all the boxes. We are saving lots of money because we don’t need the vacuum trucks anymore. We are saving lots of time and labor because our maintenance team can trust the new system to just plain work. We’re confident now that we have the right oil removal solution in place. It’s effective, efficient, rugged, and reliable—all year round.”

***

If you’re looking for THE ideal oil removal solution for your unique needs and applications, contact us today.